You look at the endless dunes of Desert, Saudi Arabia, and assume sand supply is limitless. Yet the skyscrapers rising across the Gulf depend on a very different kind of grain. This is the surprising story of how sand quality, not quantity, drives billion dollar imports from faraway shores. Stick around to see why desert softness clashes with concrete strength, and how global trade fills the gap.

1. Why desert sand falls short

Stand in Desert, Saudi Arabia and the dunes feel endless, but their grains tell another story. Wind polishes desert sand into smooth, rounded shapes that slide past each other like marbles. When mixed with cement, these grains do not interlock strongly enough to create the dense, high strength matrix modern construction demands.

Concrete prefers angular, rough edged particles that bite, grip, and distribute stress. Riverbeds, lakes, and seabeds produce this geometry through erosion and collision, not wind alone. That is why suppliers chase specific gradations and shapes instead of raw volume.

If you have ever watched fresh concrete slump or crumble, you have seen the consequence of poor grain morphology. Engineers write tight specifications to avoid that failure. So even here, among vast dunes, builders source sand that meets performance criteria you can measure in every beam and column.

2. Construction needs angular grains

Concrete is not just mud with stones. It is a carefully proportioned composite where angular, rough particles key into cement paste to resist tension and shear. Those sharp corners and flat faces create friction and mechanical lock, which is why engineers specify crushed or river derived aggregates with defined gradation.

Rounded desert particles act like ball bearings. They reduce internal friction, increase water demand, and can weaken the cured matrix under load. When a tower sways or a slab vibrates, that microscopic grip matters.

You can feel the difference with a handful. Angular sand scratches your palm and stays put, while rounded sand trickles away. Testing confirms it with higher compressive strengths and lower slump at the same water content. So builders in and around Desert, Saudi Arabia chase angularity metrics, not just truckloads, to meet safety factors and durability targets.

3. Imports from Australia, China, and Belgium

Trade ledgers tell a counterintuitive tale. Despite standing beside Desert, Saudi Arabia, buyers procure construction grade sand from Australia, China, and Belgium. The reason is simple and practical: consistent angularity, controlled silt content, and reliable gradation that pass project submittals without endless rework.

You can imagine the logistics. Bulk carriers load calibrated blends, moisture controlled and tested, then discharge at Gulf terminals where quality inspections repeat. The premium pays for predictability that keeps cranes moving and schedules intact.

Import records even show niche shipments for special mixes and finishes. Not every load is huge, but every load is specified. When a pour is scheduled for sunrise, having the right sand becomes non negotiable. In a region defined by dunes, that paradox highlights a global supply chain built around performance rather than proximity.

4. Australia’s position in global sand exports

Australia stands out in the sand trade for volume, quality control, and port infrastructure. In 2023, exports reached roughly $273 million, placing the country among the top global suppliers. What you are buying is not just grains, but certification and repeatability that keep engineers and insurers comfortable.

From dredged marine deposits to processed silica blends, exporters calibrate particle size distribution, clay content, and salt thresholds. Those details matter when you are pouring post tensioned slabs or high performance concrete in harsh climates.

For projects tied to Desert, Saudi Arabia, Australian shipments offer a dependable baseline. The paperwork travels with the cargo: sieve curves, chloride tests, and organic content limits already verified. That bundle of certainty saves time on site and reduces risk, which explains why distant beaches and quarries can outcompete closer dunes for serious structural work.

5. Saudi purchases of construction-grade sand

Saudi Arabia does buy construction grade sand from abroad, including Australia. Some consignments are small, like roughly $140,000 worth in 2023, but their impact is outsized. These targeted purchases fill specification gaps on critical timelines and specialized mixes.

You might think the number looks modest against mega budgets. That is because not every project needs imports every day. Local sources still serve many uses, but when a mix design calls for precise angularity and low fines, imported sand can be the most efficient fix.

In Desert, Saudi Arabia and across the Eastern Province, ports and logistics hubs make that strategy practical. Labs verify compliance quickly, batching plants adjust water and admixtures, and pours proceed without delay. In the ledger of risk management, that reliability is worth far more than the invoice total suggests.

6. UAE mega-project demand

Neighboring UAE anchors the region’s appetite for high performance aggregates. Dubai and Abu Dhabi build tall, fast, and with strict specifications, which often means imported sand. You see it in the steady convoys feeding ready mix plants that supply towers, bridges, and transit lines.

For Desert, Saudi Arabia, that regional demand matters because shipping lanes, suppliers, and port schedules interlink. The same carriers and quality systems support both markets. When UAE projects surge, prices and lead times ripple across the Gulf.

Builders plan around that reality. They lock contracts, prequalify multiple sources, and hold buffer inventories to ride out surges. If you are managing a pour, your calendar is chained to those logistics, which explains why imported sand is more than a commodity here. It is a timetabled, tested component of a complex urban machine.

7. Imported sand in iconic projects

Some of the Gulf’s most famous structures relied on imported sand because performance trumps proximity. The Burj Khalifa’s demanding concrete mix designs required carefully graded, angular particles to achieve pumpability and strength at height. Local desert sand could not reliably deliver those properties across all pours.

When your rebar cages climb skyward, small material choices amplify. Pump pressures, temperature control, and set times all hinge on aggregate behavior. An underperforming sand does not just weaken concrete, it chokes pumps and disrupts schedules.

You can feel the caution in every submittal binder. Certificates, sieve curves, and trial mixes stack up before a single bucket swings. That diligence shapes regional procurement, influencing projects even near Desert, Saudi Arabia. The lesson is simple: iconic results come from mundane discipline, including paying extra for sand that does exactly what the mix design says it must.

8. Artificial islands and soaring demand

Artificial islands multiply sand demand in ways that surprise even seasoned planners. Palm Jumeirah alone consumed millions of cubic metres, a volume that strains local ecosystems if mined aggressively. Importing the right material helps balance performance and environmental obligations.

For builders near Desert, Saudi Arabia, those projects set regional norms. Dredgers, reclamation techniques, and sediment control plans migrate from city to city. Specifications concentrate on settlement behavior, salt content, and long term stability under wave action.

If you stand on a fresh promenade, you are standing on logistics as much as sand. Every grain traveled, tested, and was placed to a tolerance. That scale explains why quality and source selection become strategic decisions, not just procurement tasks, especially when iconic shorelines and tourism dollars depend on lasting foundations.

9. A world hooked on sand

Sand is the world’s most used solid material by volume. UNEP estimates nearly 50 billion tonnes consumed each year, driven by urbanization, roads, and coastal works. You feel that demand in every truck rumble past Desert, Saudi Arabia and every new district plotted on a planner’s tablet.

Concrete and asphalt swallow the lion’s share. Glass, silicon, and landscaping consume more. Each sector specifies texture, gradation, and chemistry differently, which splinters the market into niches.

When demand outpaces regulated supply, prices wobble and substitution accelerates. That is why you see manufactured sand, recycled aggregates, and stricter tender specs appearing across the Gulf. The global scale is not abstract here. It is woven into delivery schedules, budget buffers, and the fine dust on your boots after site walks.

10. The global sand shortage

UNEP and industry experts warn of a tightening market for construction grade sand. Over-mined riverbeds, eroding coastlines, and stricter environmental rules constrain supply just as cities accelerate growth. You see the tension whenever tenders include sustainability clauses alongside unforgiving deadlines.

Shortage does not mean no sand exists. It means compliant, traceable, angular sand is scarce at the price and timing projects want. That nuance drives imports to Desert, Saudi Arabia even with dunes on the horizon.

Projects adapt with earlier procurement, diversified sources, and mix designs that stretch material performance. Still, when a pour window narrows, availability trumps theory. The shortage is not a headline, it is a daily calendar challenge, solved by ships, labs, and patient schedulers who keep cranes swinging.

11. Not all sand is the same

Call it sand and it sounds uniform, but the differences are everything. Desert grains are rounded and often too smooth. River and marine sands tend to be more angular, with gradations that compact and lock together for structural mixes.

Silica and industrial sands add chemistry to the mix, feeding glass and specialty mortars. Each type comes with contaminants to manage: salts, clays, organics, or sulfates. That is why submittals read like lab reports rather than brochures.

When you are building near Desert, Saudi Arabia, choosing the right sand is a design decision. The wrong choice means higher water demand, shrinkage cracks, or corrosion risks. The right choice means predictable strength and durability. It is not about abundance, it is about matching grain to job, one sieve and chloride test at a time.

12. Environmental limits on local extraction

Local extraction faces ecological guardrails for good reason. Unchecked sand mining can scar habitats, alter drainage, and trigger erosion. In Desert, Saudi Arabia, safeguarding dunes and nearby ecosystems shapes policy as much as engineering specs do.

Permits cap volumes, restrict zones, and require rehabilitation. Those rules reduce local supply just when projects accelerate. Instead of pushing fragile landscapes, buyers source compliant imports and better documentation.

If you care about resilient cities, this trade off makes sense. You preserve natural buffers against dust storms and protect biodiversity, while still meeting construction milestones. The result is a cleaner, more auditable supply chain that aligns with environmental goals and investor scrutiny.

13. Vision 2030 and material demand

Vision 2030 transforms Saudi Arabia’s built environment at record pace. NEOM, The Line, the Red Sea Project, and Qiddiya scale material demand beyond ordinary cycles. You can trace that pressure from tender books to quarry gates and shipping manifests.

For Desert, Saudi Arabia and the Eastern Province, logistics corridors become lifelines. Ready mix plants calibrate mixes for heat, pump distance, and durability, demanding sands that behave predictably. Imports plug gaps when local sources cannot meet uniformity targets.

The strategy is pragmatic. Secure multiple supply streams, test relentlessly, and keep schedules buffered. High profile projects do not gamble on uncertain inputs. They pay for certainty, and in sand that means angular grains, tight gradations, and clean chemistry delivered on time.

14. Manufactured sand and recycling

Alternatives are moving from pilot to mainstream. Manufactured sand, made by crushing rock to specific shapes, delivers angularity and controlled gradation. Recycled construction waste reduces landfill and can replace portions of natural sand in concrete and mortar.

You still need quality control. Excess fines, flaky particles, or residual chlorides can sabotage performance. Plants add washing, air classification, and admixture tweaks to dial mixes in.

For sites near Desert, Saudi Arabia, these options cut import exposure while meeting specs. They also help meet sustainability targets that lenders and clients increasingly demand. If you want resilience in your supply chain, M-sand and recycling belong in the toolbox, backed by testing and transparent documentation.

15. Industrial necessity, not simple scarcity

The paradox is real but logical. Sand rich nations import sand because engineering cares about shape, size, and chemistry more than scenery. Rounded dunes near Desert, Saudi Arabia are majestic, but they do not substitute for angular aggregates that make concrete reliable.

Imports are a tool, not a concession of failure. They deliver specification compliance at predictable timelines. Local sources still serve backfill, masonry, and landscaping, while critical pours demand verified performance.

If you manage projects here, you already live this balance. You specify, test, and source accordingly. That is industrial necessity at work, turning a landscape of abundance into a targeted supply chain built around measurable quality and risk control.

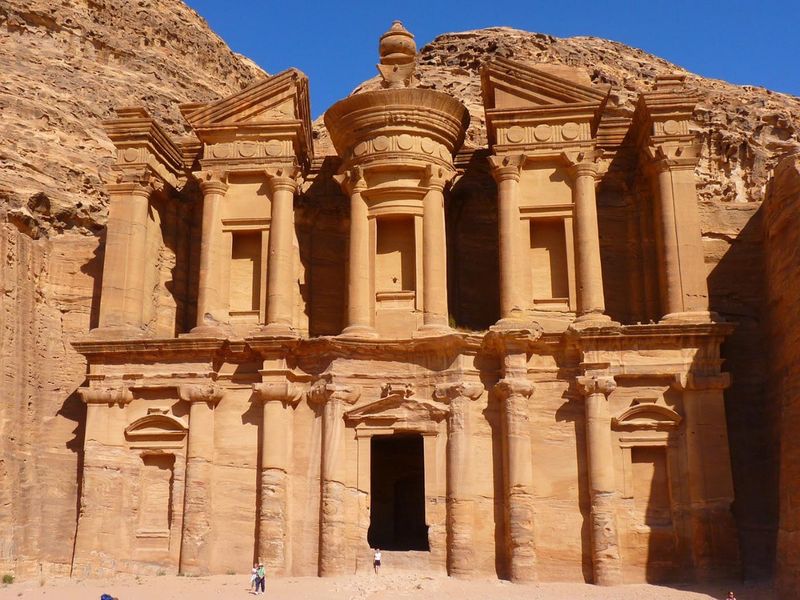

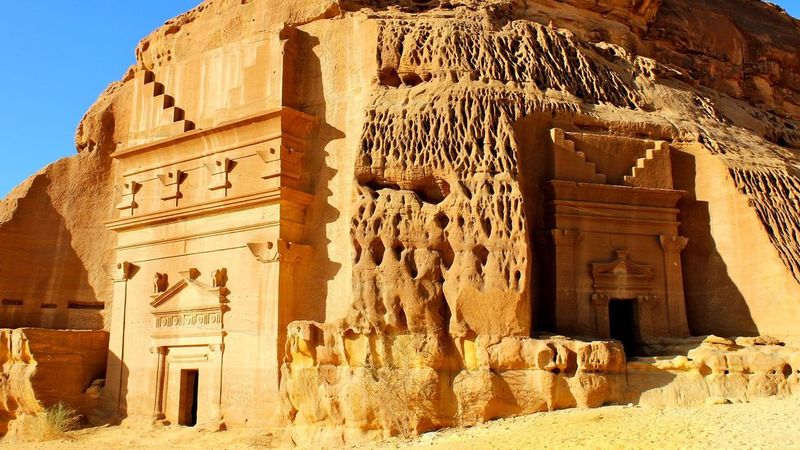

16. Visiting Desert, Saudi Arabia: sense of place

Desert, Saudi Arabia is more than a backdrop to supply chains. At sunrise the dunes glow amber, wind etches ripples, and silence blankets the horizon. You can feel why reviews rate the area highly, a 4.2 star respite where scale dwarfs worries.

Walk the ridges and the sand spills like silk between your fingers, rounded and fine. That same beauty explains why it struggles in concrete. Nature optimized for motion and grace, not mechanical lock.

Standing there, you see the paradox made tangible. Ships may carry angular grains from far shores, but the dunes carry a different value. Come for perspective, leave understanding that materials have purposes, and deserts have theirs too.